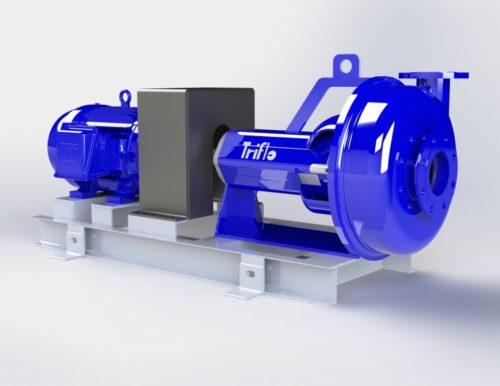

ES 500

Slurry Solutions Made Simple.

Dewatering for Environmental & Industrial Applications

Designed for flexibility in challenging field conditions, the Triflo ES 500 features a modular, compact layout that integrates seamlessly with site equipment like mud pumps, vacuum trucks, and dewatering rigs. Whether you’re managing drilling slurry, cleaning industrial ponds, or tackling large-scale environmental remediation, the ES 500 adapts to shifting jobsite needs without sacrificing performance. Its high-volume tank system and fine-particle separation capabilities help maximize fluid recovery while keeping operations clean, efficient, and compliant.

Capturing the Finer Details

Engineered for precision and performance, the Triflo ES 500 supports a wide range of slurry-heavy operations—from oil and gas drilling to wastewater treatment, deepwell dewatering, and wellpoint systems. With a processing capacity of 500 GPM, a 10-micron cut point, and over 4,200 gallons of onboard volume, the ES 500 delivers consistent results across fluid-intensive jobsites. Its rugged, user-friendly configuration streamlines setup and operation, making it a reliable asset for crews working in remote, high-demand environments.

features

HIGH-VOLUME TANK SYSTEM

Providing over 4,200 gallons of onboard tank capacity, this environmental dewatering system ensures continuous operation for large-scale drilling projects, soil remediation and construction dewatering.

FINE PARTICLE FILTRATION

Equipped with three 146E elliptical motion scalping shakers, paired with ten 4-inch desilter hydrocyclones and thirty 2-inch desilter hydrocylones, the ES 500 efficiently handles a wide range of solid sizes, adapting to diverse project needs.

Specifications

Weight and Dimensions

- Weight: 24000 lbs. (10886 kg)

- Length: 28 ft. 6 in. (8.7 m)

- Width: 7 ft. 11¾ in. (2.4 m)

- Height: 10 ft. 7 in. (3.2 m)

Tank Capacities

- Max Capacity: 4282 gal (16.21 kL)

- # of Tanks: 3

- Scalper Tank: 991 gal (3.75 kL)

- Desilter Tank 1: 1491 gal (5.64 kL)

- Desilter Tank 2: 1800 gal (6.81 kL)

Equipment

- SHALE SHAKERS:

- 3 TFI 146E Elliptical Motion Shakers

- 3 Screens Per Shaker

- Shaker Bed Area 24 ft² (2.3 m²)

- Screen Size 25" x 49.3"

- Available mesh sizes: 3 - 400 Mesh

- DESILTERS:

- 10 4-in (10.2 cm) Hydrocyclones

- 30 2-in (5.1 cm) Hydrocyclones

- PUMPS:

- 2 4x5 250 Series Centrifugal Pumps with 40HP Electric Motors

- 1 4x5 250 Series Centrifugal Pump with 30HP Electric Motor

- MUD GUNS:

- 3 Stationary Mud Guns

General

- Inlet Size: 4 in. (10.2 cm)

- Outlet Size: 4 in. (10.2 cm)

- Control Panel: Centralized Weatherproof NEMA 4x Control Panel

- Power Requirements: 165 AMPS

- Corrosion Control: Chemical/Abrasion Resistant Mastic Tank Lining

- Frame Type: Skidded

- Process Rate: 500 GPM

- Cut Point: 10µ

- Lighting: 2 Telescoping LED Work Lights

Optional Additions

- Pit Pump: TFI 4 in. Semi-Submersible

- Generator: 160 kW 460v/60Hz

- Trailor: Gooseneck/Pintle/Integrated

- Wired Remote: Pit Pump/Charge Pump

- Winterization: Tank Heaters, Pipe Insulations +

- Branding: Custom Colors and Logos

- Electrical: XP Package

Smart Slurry Management Starts Here

Remediation, dewatering, or industrial cleanup—the ES 500 is your go-to solution.