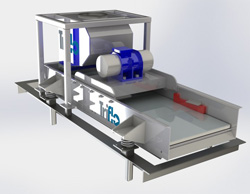

ES 2000R

Optimized for Large-Scale Environmental Recovery

Built for High-Volume Environmental Demands

The Triflo ES 2000 Rockover is engineered for efficient, high-volume solid-liquid separation—without the use of polymers or coagulants. With a 24-micron cut point, it effectively removes fine solids while reducing disposal volume and supporting water reuse. The result is a cleaner, more sustainable process that helps meet environmental regulations with ease.

Whether you’re managing short-term remediation or long-term recovery, the ES 2000R delivers consistent performance in the field.

Flow That Keeps You Moving

Built to handle serious flow rates, the ES 2000R moves up to 2,000 gallons per minute—making it ideal for large-scale environmental and industrial cleanup. From dredging and sludge recovery to pit cleanouts and tank bottom separation, this system increases jobsite efficiency while lowering haul-off costs.

Its rockover trailer design enables fast mobilization and easy transport, giving you flexibility without compromising output.

features

DESIGNED TO MOVE

The Rockover design of the ES 2000R allows effortless tilting for seamless transport and rapid deployment. Built as a non-permit load, it simplifies logistics, minimizes transportation costs, and accelerates setup for quick, efficient mobilization.

TARGETED SEPARATION

Equipped with four 10-inch desander hydrocyclones and thirty-two 4-inch desilter hydrocyclones, this system effectively captures both coarse and fine solids, ensuring optimal fluid quality and extending the longevity of the equipment.

Specifications

Weight and Dimensions

- Weight: 62840 lbs. (28503 kg)

- Length: 52 ft. 11 in. (16.1 m)

- Width: 8 ft. 4¾ in. (2.6 m)

- Height: 12 ft. 3½ in. (3.8 m)

Tank Capacities

- Max Capacity: 7976 gal (30.2 kL)

- # of Tanks: 3

- Scalper Tank: 2522 gal (9.5 kL)

- Desander Tank: 3164 gal (11.9 kL)

- Desilter Tank: 2276 gal (8.6 kL)

Equipment

- SHALE SHAKERS:

- 2 TFI 148E Elliptical Motion Shakers

- 4 Screens Per Shaker

- Shaker Bed Area 32 ft² (3 m²)

- Screen Size 25" x 49.3"

- 4 TFI 146E Elliptical Motion Shakers

- 3 Screens Per Shaker

- Shaker Bed Area 24 ft² (2.3 m²)

- Screen Size 25" x 49.3"

- Available mesh sizes: 3 - 400 Mesh

- DESANDER:

- 4 10-in (25.4 cm) Hydrocyclones

- DESILTER:

- 32 4-in (10.2 cm) Hydrocyclones

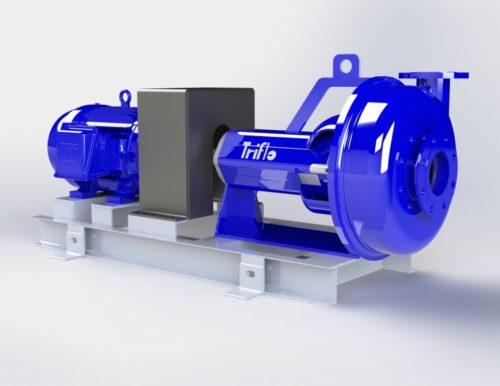

- PUMPS:

- 3 6x8 250 Series Centrifugal Pump with 75HP Electric Motor

- MUD GUNS:

- 2 Stationary Mud Guns

- AGITATORS:

- 3 10HP Agitators with 32" Paddle Blades

General

- Inlet Size: 8 in. (20.3 cm)

- Outlet Size: 6 in. (15.2 cm)

- Control Panel: Centralized Weatherproof NEMA 4x Control Panel

- Power Requirements: 330 AMPS

- Corrosion Control: Chemical/Abrasion Resistant Mastic Tank Lining

- Frame Type: Rockover

- Process Rate: 2000 GPM

- Cut Point: 24µ

- Lighting: 3 Telescoping LED Work Lights

Optional Additions

- Generator: 325 kW 460v/60Hz

- Frame: Skidded

- Winterization: Tank Heaters, Pipe Insulations +

- Branding: Custom Colors and Logos

- Electrical: XP Package

Tough Jobs. High Flow. One Solution.

Take control of sludge, sediment, and recovery challenges with the ES 2000R.