MFS 3500S

Mid-Size System. Full-Scale Performance.

Designed for Demand

The MFS 3500 is purpose-built for high-efficiency solids control in Horizontal Directional Drilling, microtunneling, and similar trenchless applications. Its mid-size capacity bridges the gap between compact systems and full-scale reclaimers—delivering the flow rate and separation power required for longer bores and more complex utility installations, with cut point performance down to 24 microns.

Scalable for Complex Jobsites

With a 600 GPM throughput and streamlined layout, the MFS 3500 is ideal for contractors who need dependable performance in environments where uptime and space are critical. From urban infrastructure work to remote field operations, it integrates easily with most drill setups—keeping your fluid clean and your timeline on track.

features

Powerful Performance

The MFS 3500 offers a mid-size, skid-mounted design that integrates easily with a wide range of drilling rigs and support equipment. With a 600 GPM continuous process rate, it supports consistent mud flow and reduces downtime in the field.

Advanced Solids Separation

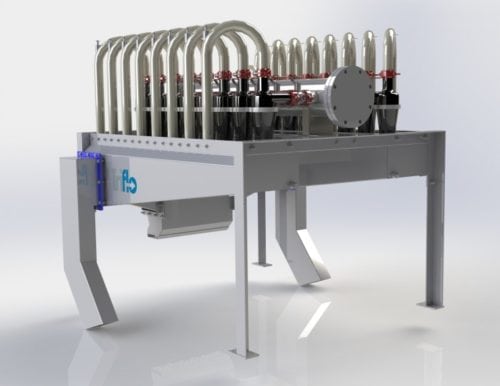

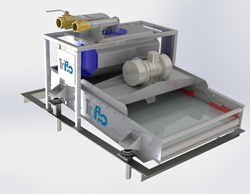

Two elliptical motion scalping shakers efficiently remove large particles, while twelve 4-inch hydrocyclones target fine solids—ensuring a consistent supply of clean, high-quality mud throughout your operation.

CONSISTENT FLUID CIRCULATION

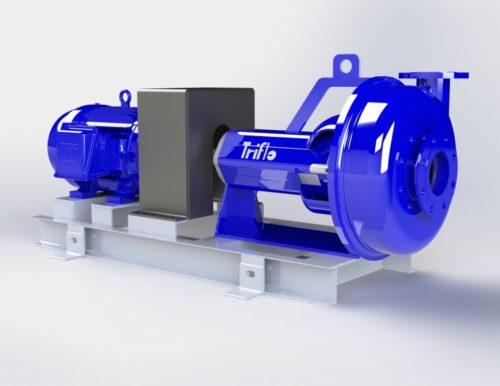

Equipped with three centrifugal pumps, the MFS 3500 delivers a steady and controlled flow, keeping the mud system balanced and providing optimal pressure for each stage of solids separation.

Specifications

Weight and Dimensions

- Weight: 19500 lbs. (8845 kg)

- Length: 24 ft. 6 in. (7.5 m)

- Width: 7 ft. 7 in. (2.3 m)

- Height: 10 ft. (3 m)

Tank Capacities

- Max Capacity: 3228 gal (12.22 kL)

- # of Tanks: 2

- Scalper Tank: 1302 gal (4.93 kL)

- Desilter Tank: 1926 gal (7.29 kL)

Equipment

- SHALE SHAKERS:

- 2 TFI 146E Elliptical Motion Shakers

- 3 Screens Per Shaker

- Shaker Bed Area 24 ft² (2.3 m²)

- Screen Size 25" x 49.3"

- Available mesh sizes: 3 - 400 Mesh

- DESILTER:

- 12 4-in (10.2 cm) Hydrocyclones

- PUMPS:

- 2 4x5 250 Series Centrifugal Pumps with 30HP Electric Motors

- 1 4x5 250 Series Centrifugal Pumps with 40HP Electric Motors

- MUD GUNS:

- 1 Stationary Mud Gun

- 2 Swivel Mud Guns

- HOPPER:

- 1 TFI 4 in. Mud Hopper with Venturi Jet

General

- Inlet Size: 4 in. (10.2 cm)

- Outlet Size: 4 in. (10.2 cm)

- Control Panel: Centralized Weatherproof NEMA 4x Control Panel

- Power Requirements: 147 AMPS

- Corrosion Control: Chemical/Abrasion Resistant Mastic Tank Lining

- Frame Type: Skidded

- Process Rate: 600 GPM

- Cut Point: 24µ

- Lighting: 2 Telescoping LED Work Lights

Optional Additions

- Pit Pump: TFI 4 in. Semi-Submersible

- Generator: 150 kW 460v/60Hz

- Trailor: Gooseneck/Pintle/Integrated

- Wired Remote: Pit Pump/Charge Pump

- Winterization: Tank Heaters, Pipe Insulations +

- Branding: Custom Colors and Logos

- Electrical: XP Package

Optimize Your Operations

Let’s talk about how the MFS 3500 can fit your project needs.