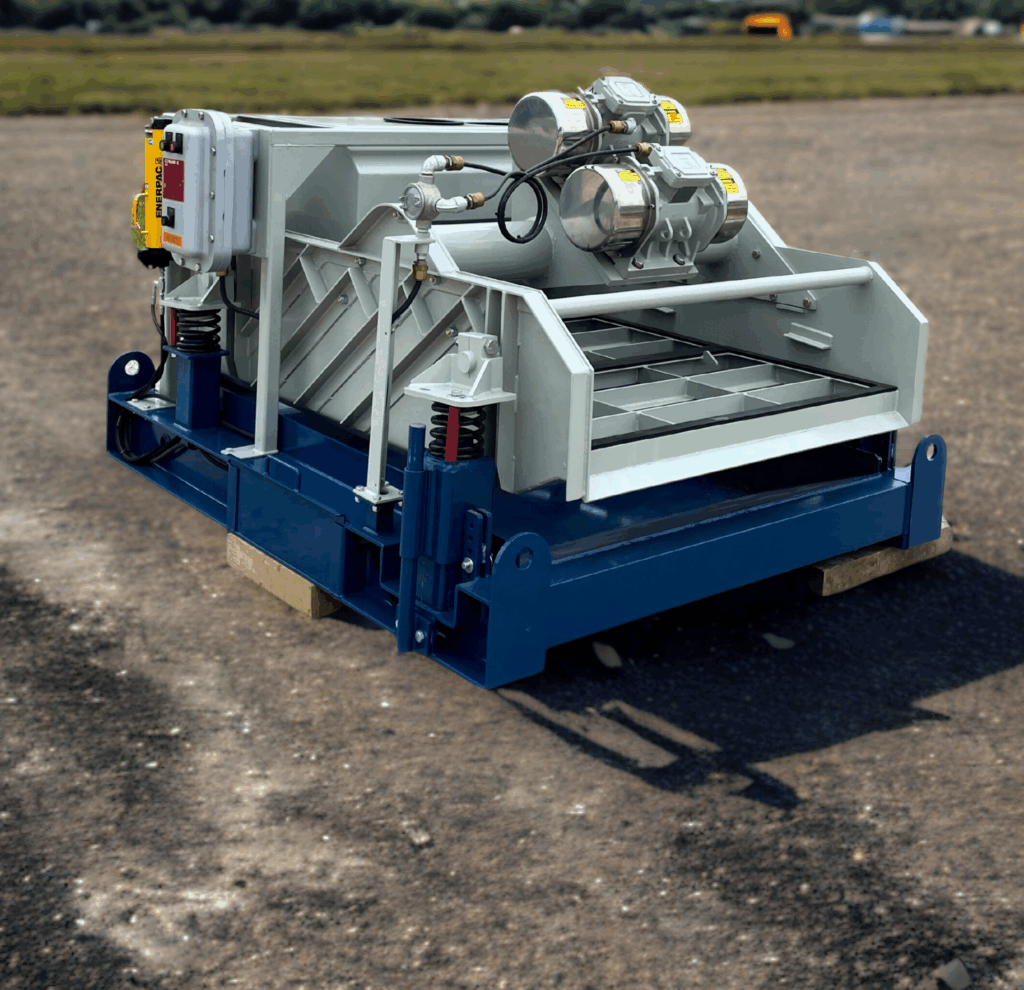

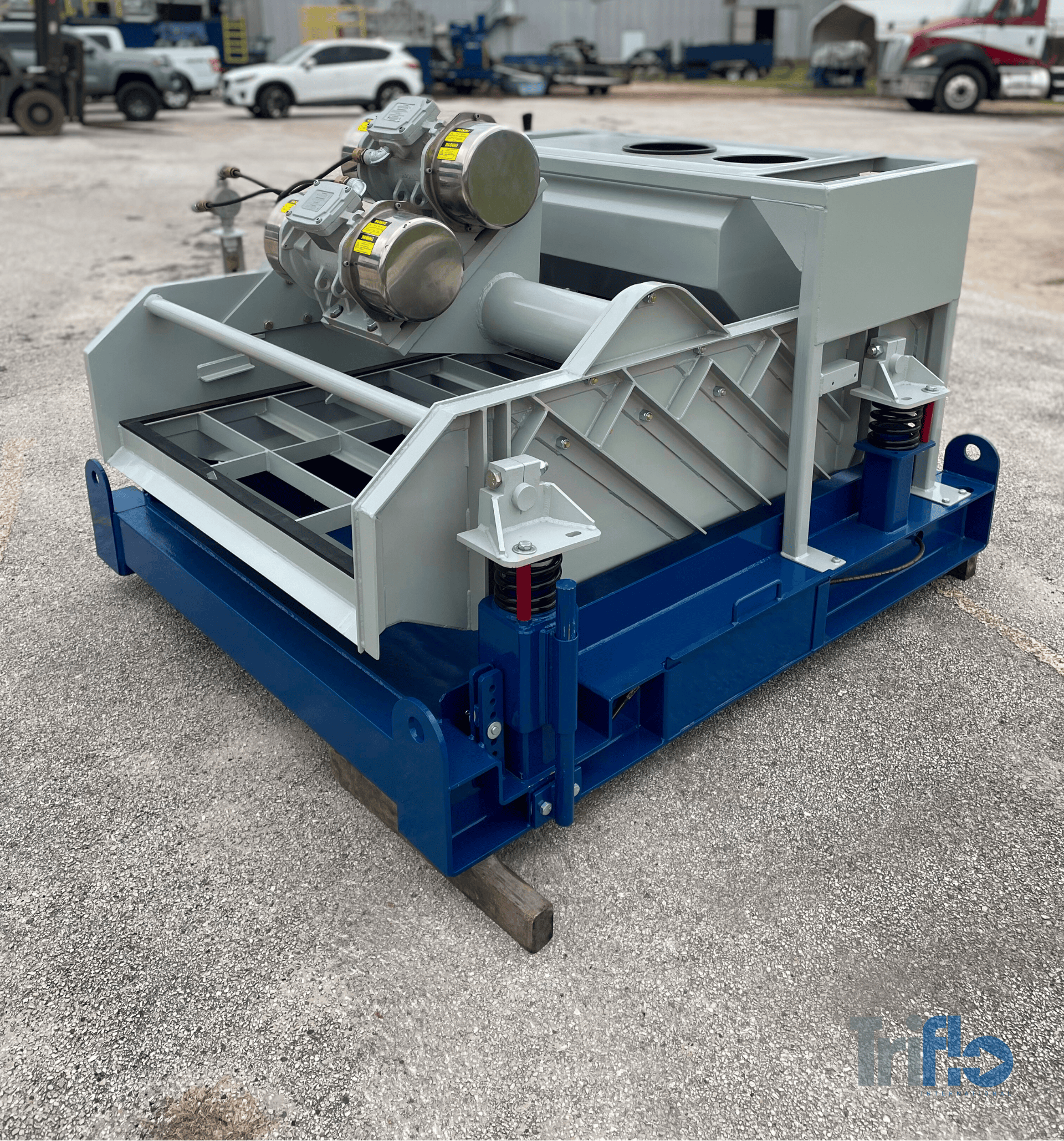

146L

Energy Efficient

Motors

Quick Screen Replacement

Expanded Shaker

Deck

146L

Linear Motion Shaker

Built for high-volume drilling, the Triflo 146L delivers aggressive linear motion for fast cuttings conveyance and maximum fluid recovery. With 24 ft² of screening area and rugged in-house construction, it’s a dependable shaker that combines capacity, efficiency, and durability in one streamlined design.

Performance Features:

Linear motion generates aggressive cuttings conveyance, ideal for high-volume solids control.

Large screening area provides consistent throughput with minimal fluid loss.

Adjustable G-force allows fine-tuning for varying drilling conditions.

Rugged frame and vibration isolation reduce downtime and extend service life.

Specifications

Weight and Dimensions

- Weight:

- Length: 6 ft. 8 ⁹⁄₁₆ in.

- Width: 6 ft. 3 ¹³⁄₁₆ in.

- Height: 4 ft. 2 ⅜ in.

Screens

- # of Screens: 3

- Screen Size: 25" x 49.3"

- Screen Type: Pre-tensioned

- Available mesh sizes: 3 - 400 Mesh

- Shaker Bed Area: 24 ft² (2.3 m²)

General

- Power Requirements: 67 AMPS

- Corrosion Control: Chemical/Abrasion Resistant Mastic Tank Lining

- Frame Type: Skidded

- Process Rate: 500 GPM

- Cut Point:

Optional Additions

- Winterization:

- Branding: Custom Colors and Logos

- Electrical: XP Package

Manage heavy loads of solids across a wide range of demanding applications.

Industrial-Grade Separation, Wherever It's Needed

Drilling Fluid Conditioning

Removes solids from drilling slurries in HDD, water well, and civil construction to extend fluid life by maintaining integrity and reduce wear on downstream equipment.

Tank and Pit Cleaning

Separates settled solids from tank bottoms and pit floors during pump-out or washdown. The smooth elliptical motion keeps flow consistent without over-agitating thick sludge.

Wastewater Screening

Screens solids from overflow or bypass systems to prevent excess solids from entering waterways. Commonly used to relieve overloaded settling ponds, enabling the recovery and reuse of manure-rich water.

Agricultural Screening

Sifts corn, grain, or feedstock to remove clumps, husks, and debris before processing or packaging.

Slurry Separation

Handles high-solids slurries in remediation, mining, or washdown systems to reduce disposal volume.

Fluid Reclamation

Screens recycled or stored fluids for reuse during extended runs in trenchless, geothermal, and utility work.

Find high-quality replacement parts and OEM-compatible screens that fit all major shaker brands

Keep Your Shaker Running Strong

Explore our full range of mesh sizes and screen styles, including OEM replacement screens compatible with other major shaker brands.

Browse our selection of shaker replacement parts, including OEM-compatible components for other major brands, to keep your equipment running efficiently and minimize downtime.