In the construction industry, groundwater can create a host of complications that affect both worker safety and structural stability. Dewatering is a critical aspect of maintaining a safe construction site. Whether you are pouring a concrete slab or excavating a pipeline, dewatering improves your construction quality, decreases labor hours, and promotes worksite safety.

Since 1979, Triflo has been an industry leader in the design and manufacture of dewatering solutions for our customers in the construction industry. We offer outstanding construction project dewatering equipment for both surface water and groundwater in a variety of settings. Each of our dewatering plans is specifically designed to meet the particular needs of your site, including groundwater levels, soil porosity, site depth, and weather conditions. No matter how complex, Triflo works closely with site management to provide safe, efficient dewatering solutions for your construction project.

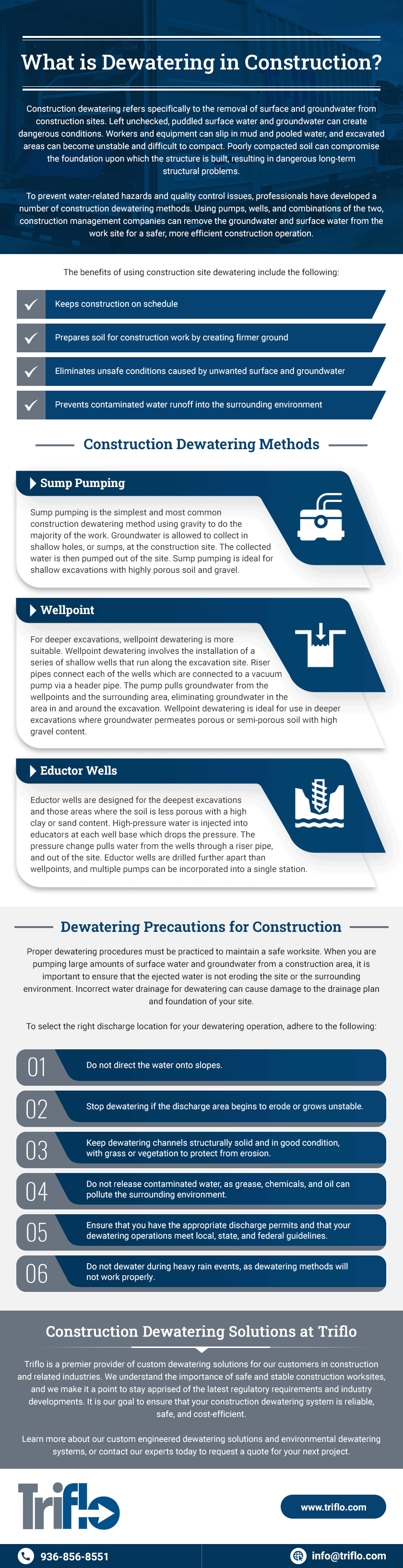

What is Dewatering in Construction?

Construction dewatering refers specifically to the removal of surface and groundwater from construction sites. Left unchecked, puddled surface water and groundwater can create dangerous conditions. Workers and equipment can slip in mud and pooled water, and excavated areas can become unstable and difficult to compact. Poorly compacted soil can compromise the foundation upon which the structure is built, resulting in dangerous long-term structural problems.

To prevent water-related hazards and quality control issues, professionals have developed a number of construction dewatering methods. Using pumps, wells, and combinations of the two, construction management companies can remove the groundwater and surface water from the work site for a safer, more efficient construction operation.

The benefits of using construction site dewatering include the following:

- Keeps construction on schedule

- Prepares soil for construction work by creating firmer ground

- Eliminates unsafe conditions caused by unwanted surface and groundwater

- Prevents contaminated water runoff into the surrounding environment

Construction Dewatering Methods

Conditions differ from site to site, making it essential to choose the right dewatering method for your specific conditions. There are a number of dewatering methods used specifically in the construction industry. The three primary dewatering methods used by construction companies are:

Sump Pumping

Sump pumping is the simplest and most common construction dewatering method using gravity to do the majority of the work. Groundwater is allowed to collect in shallow holes, or sumps, at the construction site. The collected water is then pumped out of the site. Sump pumping is ideal for shallow excavations with highly porous soil and gravel.

Wellpoint

For deeper excavations, wellpoint dewatering is more suitable. Wellpoint dewatering involves the installation of a series of shallow wells that run along the excavation site. Riser pipes connect each of the wells which are connected to a vacuum pump via a header pipe. The pump pulls groundwater from the wellpoints and the surrounding area, eliminating groundwater in the area in and around the excavation. Wellpoint dewatering is ideal for use in deeper excavations where groundwater permeates porous or semi-porous soil with high gravel content.

Eductor Wells

Eductor wells are designed for the deepest excavations and those areas where the soil is less porous with a high clay or sand content. High-pressure water is injected into educators at each well base which drops the pressure. The pressure change pulls water from the wells through a riser pipe, and out of the site. Eductor wells are drilled further apart than wellpoints, and multiple pumps can be incorporated into a single station.

Dewatering Precautions for Construction

Proper dewatering procedures must be practiced to maintain a safe worksite. When you are pumping large amounts of surface water and groundwater from a construction area, it is important to ensure that the ejected water is not eroding the site or the surrounding environment. Incorrect water drainage for dewatering can cause damage to the drainage plan and foundation of your site.

To select the right discharge location for your dewatering operation, adhere to the following:

- Do not direct the water onto slopes.

- Stop dewatering if the discharge area begins to erode or grows unstable.

- Keep dewatering channels structurally solid and in good condition, with grass or vegetation to protect from erosion.

- Do not release contaminated water, as grease, chemicals, and oil can pollute the surrounding environment.

- Ensure that you have the appropriate discharge permits and that your dewatering operations meet local, state, and federal guidelines.

- Do not dewater during heavy rain events, as dewatering methods will not work properly.

Construction Dewatering Solutions at Triflo

Triflo is a premier provider of custom dewatering solutions for our customers in construction and related industries. We understand the importance of safe and stable construction worksites, and we make it a point to stay apprised of the latest regulatory requirements and industry developments. It is our goal to ensure that your construction dewatering system is reliable, safe, and cost-efficient.

Learn more about our custom engineered dewatering solutions and environmental dewatering systems, or contact our experts today to request a quote for your next project.